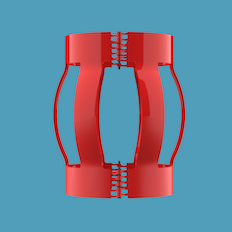

CASE STUDY Unique new S2 Hinged centralizer provides solution for drill ship in eastern mediterranean

THE CHALLENGE

Energean, together with Stena Drilling, required a hinged, non-welded bow spring centralizer compatible with the drill ship’s technical specifications. Apart from robustness and performance, further considerations were the volumetric weight, for both transport and storage offshore, and a quick and safe installation on location.

THE SOLUTION

The new Centek S2 Hinged centralizer was deemed to be perfect for the job. It is proven to be as strong and as rigid as the S2 centralizer with the same downhole performance. All with the additional benefits of up to 30% lower transport and storage cost and fast and easy installation on site.

THE RESULT

Energean used the newly developed 9 5/8” x 12 1/4” S2 Hinged centralizers in their 4 wells campaign in the Karish fields. The 9 5/8” casing was run through a previous set casing of 13 5/8” 88.2 ppf with a 12.25” ID into a 12.25” open hole. Average depth of the 9 5/8” casing was 4,900 meters. The wells had a maximum deviation of 60 degrees.

CUSTOMER TESTIMONIAL

"The redesigned Centek S2 Hinged centralizer performed great, supporting the RIH and providing the stand-off needed for a good cement job and zonal isolation, while in the same time reducing the costs associated with transport, storage and installation offshore"

Alexandru D – Halliburton Cementing