Product Summary

Centek's Cutting-Edge Centralizers: Revolutionizing Downhole Performance

In 2001, Centek made a groundbreaking advancement by developing centralizers that drastically improved downhole performance. Over the past 20 years, these innovations have significantly reduced failures and saved operators both time and money in reaching Total Depth (TD).

Leading the Way in Centralizer Excellence

Achieving and maintaining excellence in our industry is no easy feat. Yet, being a leader is far more rewarding than following the crowd. At Centek, we've set new standards and created a whole new category of centralizers. Our commitment to innovation has established us as global leaders in the market.

Why Centek Centralizers Stand Out

Our centralizers excel in six crucial areas:

- Strength: Built to endure extreme conditions.

- Flexibility: Adapts to various downhole environments.

- Runability: Easy to handle and install.

- Flow by Area: Enhances fluid flow efficiency.

- Pipe Rotation: Supports smooth pipe movement.

- Stand-off: Maintains optimal positioning.

Comprehensive Product Range

We offer a full lineup of bow spring and solid body centralizers, plus slip-on and latch-on stop collars. Our goal is to help you choose the best product that delivers high performance while considering your budget.

Tailored Solutions for Every Region

We understand that different regions have unique needs. That’s why we tailor our products to meet specific regional demands. Our line of welded and solid centralizers provides Centek's renowned quality at a competitive price, especially for less challenging wells.

Unmatched Quality and Testing

All our products are crafted to meet exact specifications and undergo extensive testing beyond industry standards. With Centek, you can be confident that you’re getting reliable, high-performance centralizers.

Explore our range and discover how Centek's innovative solutions can enhance your operations!

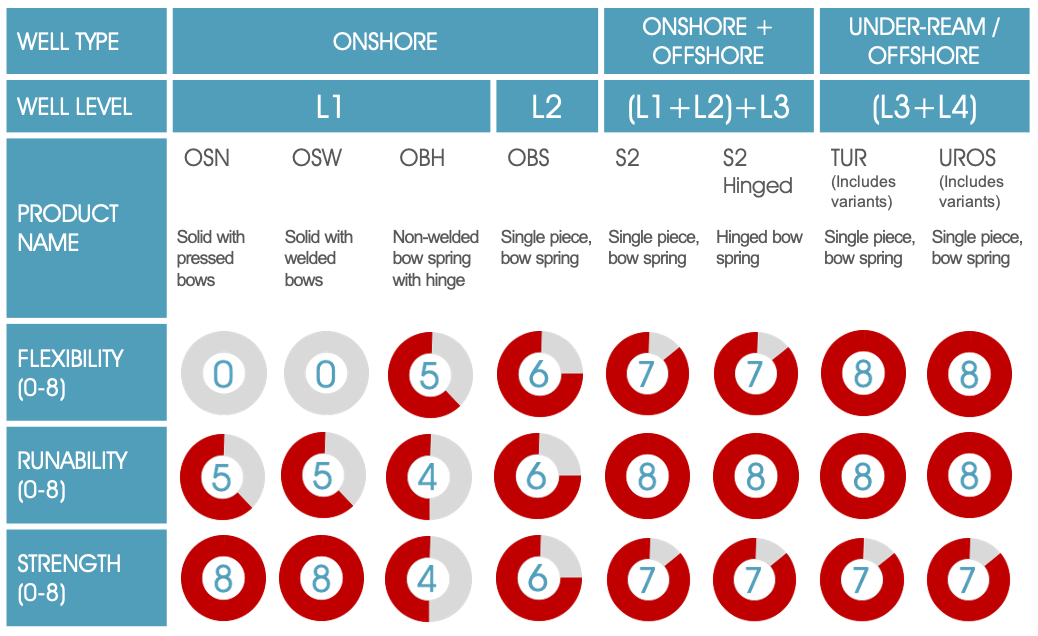

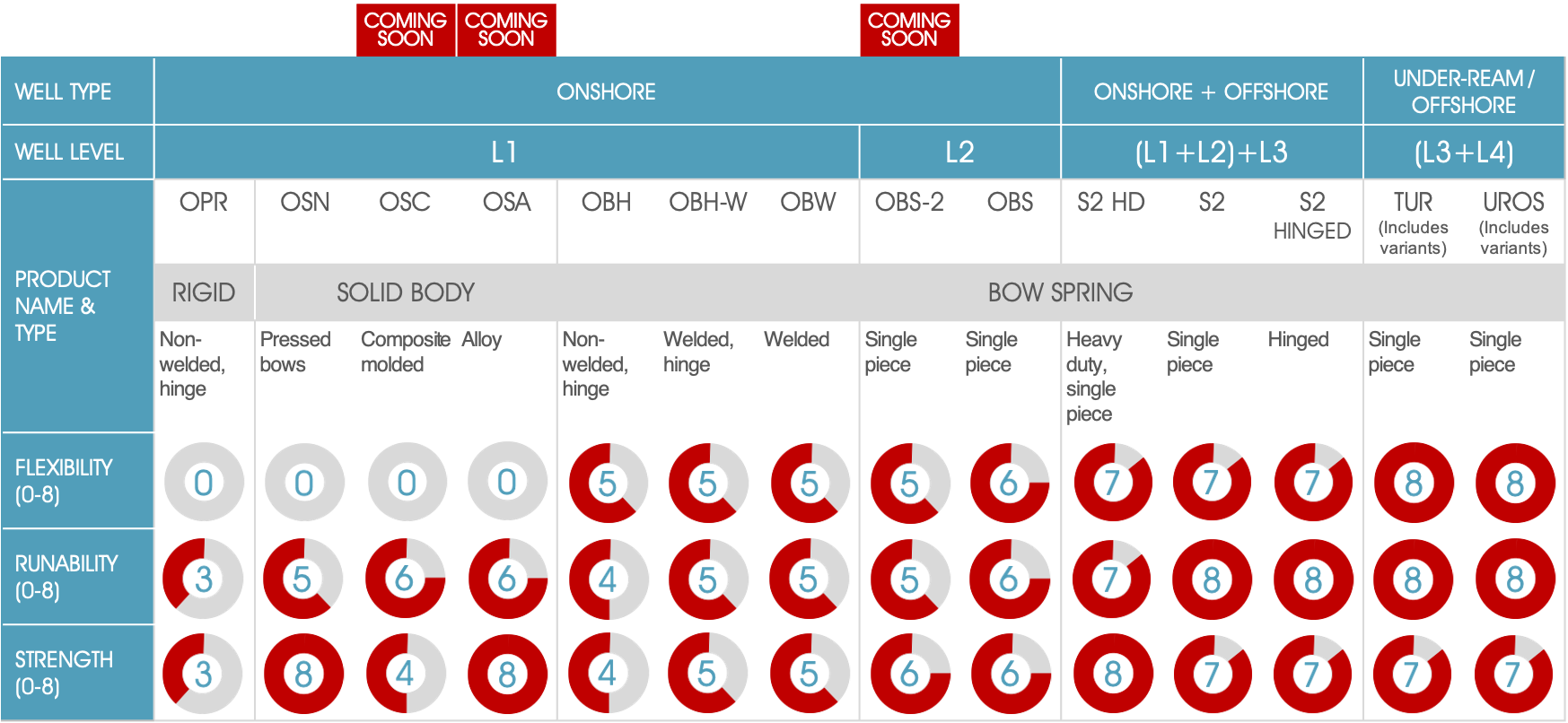

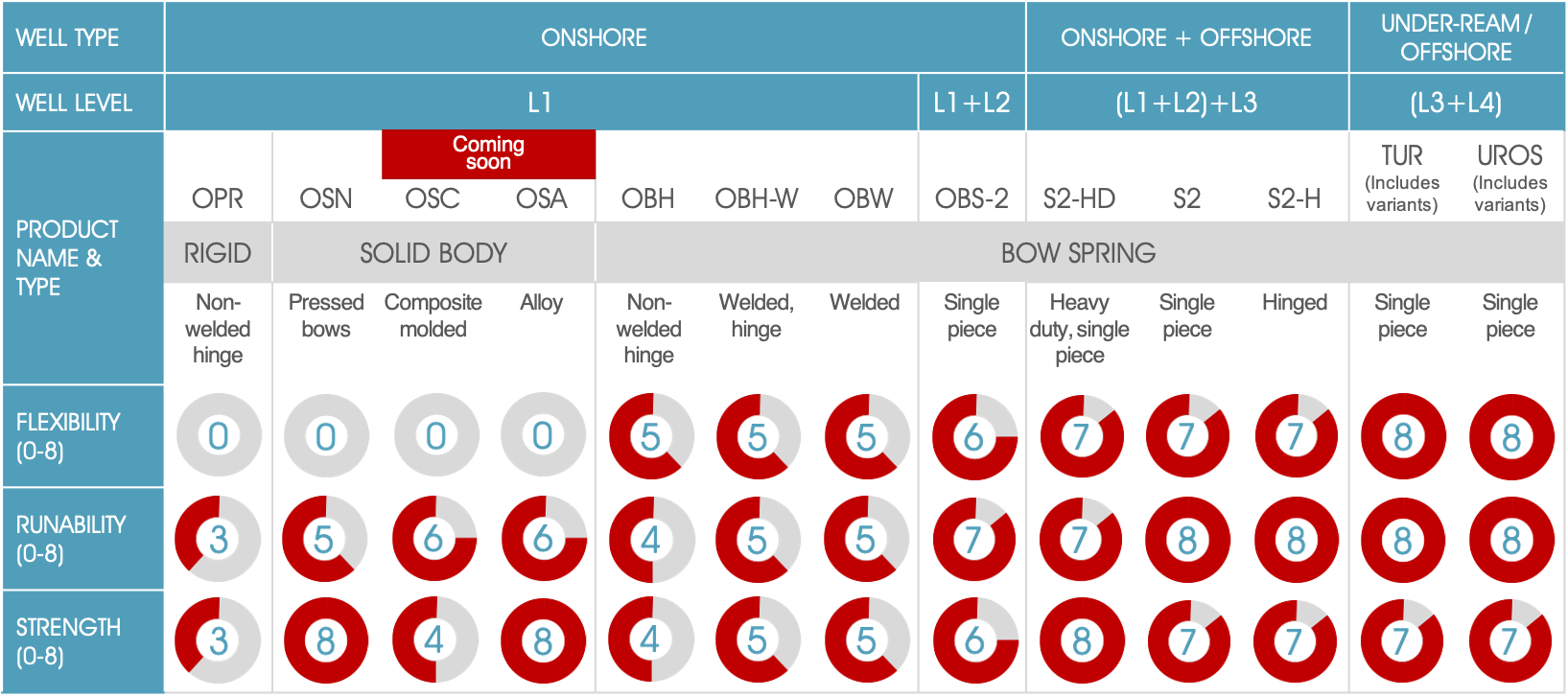

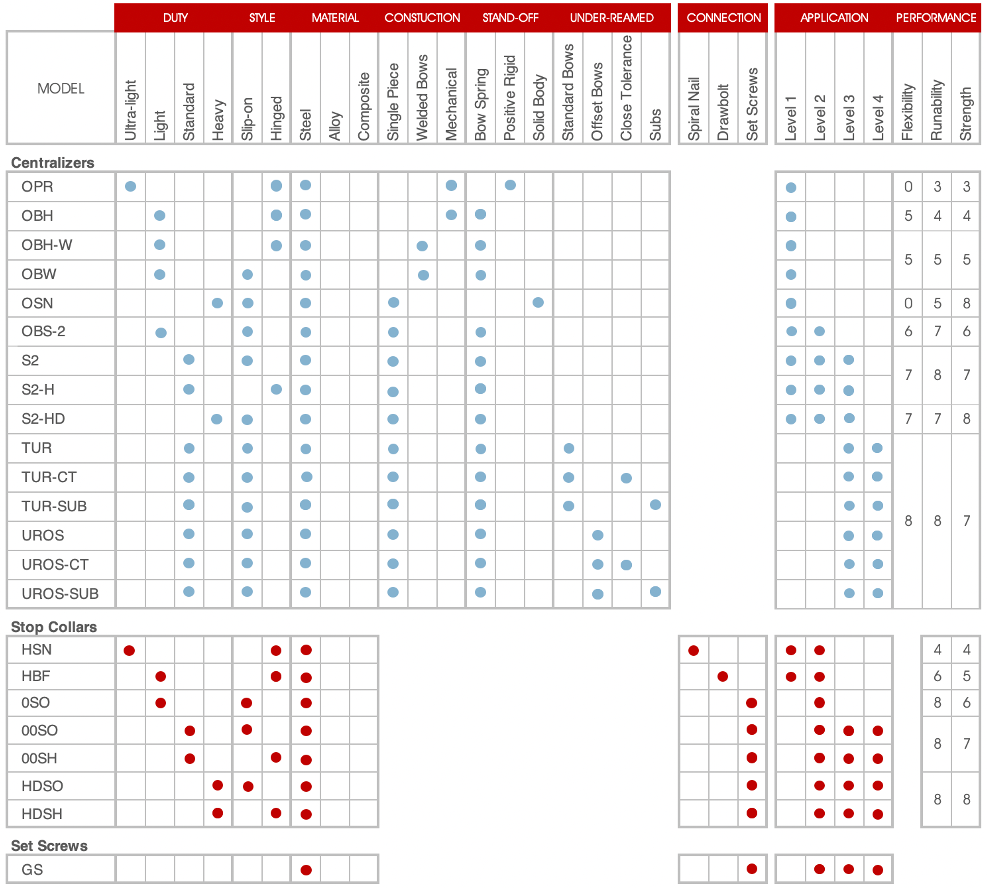

Ratings

Centralization and ease of running casing are critical factors, balancing strength and flexibility for optimal "runability." To aid product selection, we've introduced ratings for flexibility, runability, and inherent strength. These ratings help in choosing the right product for the job, considering both cost-effectiveness and the challenges of the well section.

Centek Single-Piece Centralizers

Pioneering Design and Innovation

Centek’s single-piece centralizers are a game-changer in the industry. Engineered with revolutionary design and cutting-edge innovation, these centralizers are built to last. They’re ultra-strong, designed to maintain their integrity while maximizing stand-off and preventing cement channeling. Our patented bow spring design offers unmatched flexibility, even in tight spaces, marking the biggest leap in centralizer technology in over 40 years.

Flexibility for Under-Gauge Conditions

In challenging under-gauge conditions, flexibility is key to avoiding centralizer damage and stuck pipes, which can lead to costly delays. Our single-piece centralizers excel in these situations, compressing almost flat in restricted areas and expanding to fit larger hole sizes without causing damage.

Advantages of our downhole flexibility include:

- Improved Running In Hole (RIH) in restricted areas

- No need for additional bit runs

- Maintained centralizer integrity

Superior Flow by Area

Flow by area is crucial for effective cementing operations, impacting fluid volume, velocity, density, and pressure. Our bow spring centralizers are proven to enhance annular flow by area, improving overall performance in cementing jobs.

Enhanced Pipe Rotation

Pipe rotation is essential for efficient cement displacement, which leads to better mud removal and a strong, long-lasting cement bond. Centek’s bow spring centralizers facilitate smooth pipe rotation with minimal friction, ensuring a well-centered pipe rotates freely within the centralizer while the centralizer stays firmly in place.

Benefits include:

- Improved pipe rotation and centralization

- Better well clean-out

- Superior cement job and zonal isolation

- Reduced rotational torque losses

- Minimized stall-out effects

Optimal Standoff

Standoff is the distance between the casing and the wellbore, and it’s crucial for effective cementing. A higher standoff ratio means better pipe centralization, which directly impacts displacement efficiency. Our single-piece centralizers offer excellent standoff capability, ensuring effective cementing and minimizing issues like cement channeling and low points in the well.

Key benefits of optimal standoff:

- Enhanced RIH

- Improved cementation operations

- Better pipe centralization

- Increased ECD (Equivalent Circulating Density) for higher pump rates

- Effective well clean-out

Centek’s single-piece centralizers are designed to deliver superior performance in a variety of well conditions, helping you achieve the best possible results for your operations.

Product range by style, application and performance

For more information on our products talk to our Product Service Experts today.