CASE STUDY Successful liner running operation and reciprocation achieved on bottom with Centek S2

THE CHALLENGE

Petroamazonas had a critical land well project in Ecuador in South America and had found it viable to drill on a re-entry well. A kick off window would be needed and it would be a challenge to get an open hole wellbore in good condition due to particular geological conditions found in this field.

Challenges would be to reach TD through the heterogeneous wellbore and also achieve zonal isolation between high pressure formations and depleted zones. According to Haliburton iCem simulations and experience on this field, centralization needed to be optimal along the string to keep pipe separated from depleted zones and also to get good displacement efficiency and cement annular seals, since in this well there was limitations in the ability to rotate the liner.

About the well: This well was located in the Oso Field. The original wellbore casing of 9 5/8” had a kick-off at 7,808ft. The planned well would have a depth of 10,868ft MD (9,482ft TD) with the build inclination to 38 degrees. The 3,060ft of open hole size would be 8 1/2”. The liner selected would be 7”.

THE SOLUTION

Halliburton proposed using the Centek S2 7” x 8 1/2” centralizers. These were chosen for their ruggedness and best selection for passing through the KOP exit window without problems (not once but twice!). Halliburton ICEM and Centek Latload modeling recommended locating two centralizers per joint mostly all along the open hole to give the best possible stand-off and chances of success with this cement job.

Simulations showed that running the liner and achieving good cement sheath would be possible. Halliburton pumped an ElastiCem Wellife slurry on this job to provide optimal zonal isolation along productive life of the well, which has various pay zones.

THE RESULT

In the first liner run there were external conditions that created packing-off during circulation. Close to TD the liner had to be pulled out of hole. All centralizers and stop collars were recovered in good shape.

After the conditioning trip the very same Centek centralizers and stop collars were inspected and all were re-used in the second liner run, avoiding extra costs and awaiting delivery of additional centralizers.

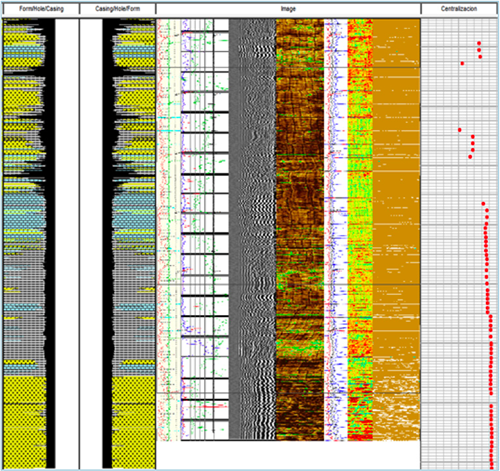

The production 7” liner reached TD without any problems. Due to torque limitations it was not possible to rotate the string when on bottom, but the Operator was able to reciprocate during circulation and cementing job. This allowed for good mud displacement efficiency and placement of cement all along and around the liner, despite the heterogeneous conditions of wellbore. This was reflected in the cement bond log.

CUSTOMER TESTIMONIAL

“The reliability of the centralizers is not in doubt for these types of well conditions or the procedure and actions taken.

Customer testimonial

The Centek S2 single piece construction gives it robustness and strength which exceeds that of competitor products. Although Centek does not recommend the re-use of centralizers after they have been pulled out of hole this case study proves that even when subjected to extreme stresses the unique design of Centek centralizers meant that they remained in good condition and could be re-run.