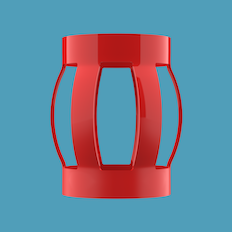

CASE STUDY Centek S2 centralizers help operator achieve cementing success

THE CHALLENGE

In this 20,000ft MD Bakken well, the operator was looking a cementing programme which provided a more productive well that lasted longer without remedial intervention and repair. They were concerned with getting the casing to bottom, the ability to rotate the casing and achieving a satisfactory bond log result

THE SOLUTION

The operator ran 471 4 1/2” x 6 1/8” Centek S2 centralizers, 2 per joint in the curve and lateral. This was to match a previous well placement comparison where plastic polymer centralizers were run. Typical rigid centralizers are built to be under hole gauge. The Centek S2 is made to hole gauge and offers semi-rigid bow spring performance and offers better standoff.

THE RESULT

All goals were achieved and the string reached total depth without issue.