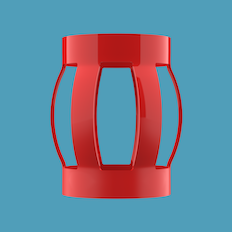

CASE STUDY New centralizer designed, tested and brought to market in 8 weeks

THE CHALLENGE

To ensure a good cement job in a well with a depth of 1,545mMD, inclination 30 degree and hole size at TD of 12.25”, in the Dutch North Sea, and to maximize core recovery in the chalk reservoir where the reservoir was cored in 12.25”. The production casing run in the section was 7”.

Good centralization and cementation of the 7” production casing in the 12.25” hole was essential to avoid migration of hydrocarbons and problems with the frac treatment in a later stage.

After a review of the market, it was found that no centralizers for 7” casing in a 12.25” hole, with the desired properties, were available.

THE SOLUTION

Centek designed and tested a 7" x 12.25” centralizer within 8 weeks.

THE RESULT

The delivery of the centralizers was within agreed delivery timings, with no delays.

The 7” casing was run without any issues and problems. There were no restrictions observed and no problems getting the casing in the ground. There were also no issues during the cement job.

CBL log showed good cemented casing.

CUSTOMER TESTIMONIAL

"Good decision to use the Centeks. Due to the development costs we had to invest more money, but the job went well and the investment was worth the money."

Drilling Engineer at Wintershall