CASE STUDY Success on second trip in hole!

South America customer in Ecuador Yuralpa Field encounters casing running problems and successfully re-runs the same Centek Centralizers on second trip in hole.

THE CHALLENGE

Occasionally casing doesn’t make it to total depth on the first run as anticipated and as planned. Today's complicated well designs and well conditions can lead to taking counter measures when running casing. Nobody considers that the centralizers may have to make 3 measured trips; trip in, pull out, and run back into the well bore. Sometimes after the trip out, typical standard welded bow spring centralizers are not always found to be intact or in a condition to be re-run.

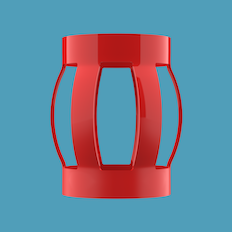

Centek Centralizers with their unique non-weld slip-on design offer high performance with the integrity and rigidity to survive these extended casing trips and harsh well environments.

A South America customer in Ecuador in the Yuralpa Field was drilling a land well that was a re-drill design with a kick-off exit window. Centralization needed to be optimal along the string to keep pipe separated from different zones and also to get good displacement efficiency and cement sheath during primary cementing procedures. The centralizers had to be of a favorable rugged design in order to pass through the exit window.

About the well: The original cased wellbore casing was 13 3/8 in. The planned well would have a depth of 9,850 ft. The open hole size at exit window would be 12 1/4 inches. The liner selected would be 9 5/8 inches.

THE SOLUTION

The customer’s original centralizer choice was with another vendor. This supplier could not provide the technical and performance testing data needed to provide a feeling of probable success to the customer.

Halliburton was asked to provide a solution and proposed using the Centek S2 9 5/8”x 12 1/4” centralizers. These were chosen for their ruggedness and best selection for passing through the KOP exit window without problems.

Information was taken from the Centek Performance Data Sheets, and along with Halliburton iCEM and Centek Latload modeling, proper placement was confirmed to give the best possible stand-off and enhancing success with the cement job.

THE RESULT

In the first liner run there were well conditions (not centralizer related) that prevented the casing making it past 7,803 feet in the wellbore. The liner could be circulated, rotated, and reciprocated, but no further movement deeper could be made. The liner had to be pulled out of hole.

All Centek centralizers and stop collars were recovered and inspected to be found in good condition. The stop rings had not moved and the centralizers were still in their original positions on the casing.

There were areas where the powder coating had been removed, but there were no signs of bent bows or bent centralizers. After the clean out and well conditioning trip, the very same Centek centralizers and stop collars were reused on the second liner run, avoiding extra costs and awaiting delivery of additional centralizers.

The 9 5/8” liner was re-run and reached TD without any problems. The centralizers had been run 25,456 feet on a 9,850 foot wellbore design and had gone through an exit window twice. The cementing job on the liner was performed as per design. Customer was happy with the results and is now planning to use Centek centralizers on future wells.

The Centek S2 single piece construction gives it robustness and strength which exceeds that of many competitor products. Although Centek does not recommend the re-use of centralizers when pulled this case study proves that even when subjected to extreme stresses the unique design of Centek centralizers meant that they remained in good condition and could be re-run.