CASE STUDY CENTEK ES CENTRALIZER TRIAL DEMONSTRATES SUPERIOR PERFORMANCE

A Turkish operator, working with a global distributor, sought technical advice from Centek after initial discussions. Based on the information provided, they decided to replace another supplier's centralizers with Centek’s ES design—confident that Centek’s expert support, advanced simulations, and precision manufacturing would deliver measurable improvement.

THE CHALLENGE

During a 7” casing operation in the Edirne region in West Turkey, the team faced typical issues from well deviation, lateral loading, and severe open hole excess. The initially selected competitor centralizers raised concerns over inadequate standoff and poor cement coverage, visible in bond logs. Centek, in collaboration with the global distributor, was invited to review the centralization plan, assess technical requirements, and present an optimized solution to improve well integrity and cement quality.

THE SOLUTION

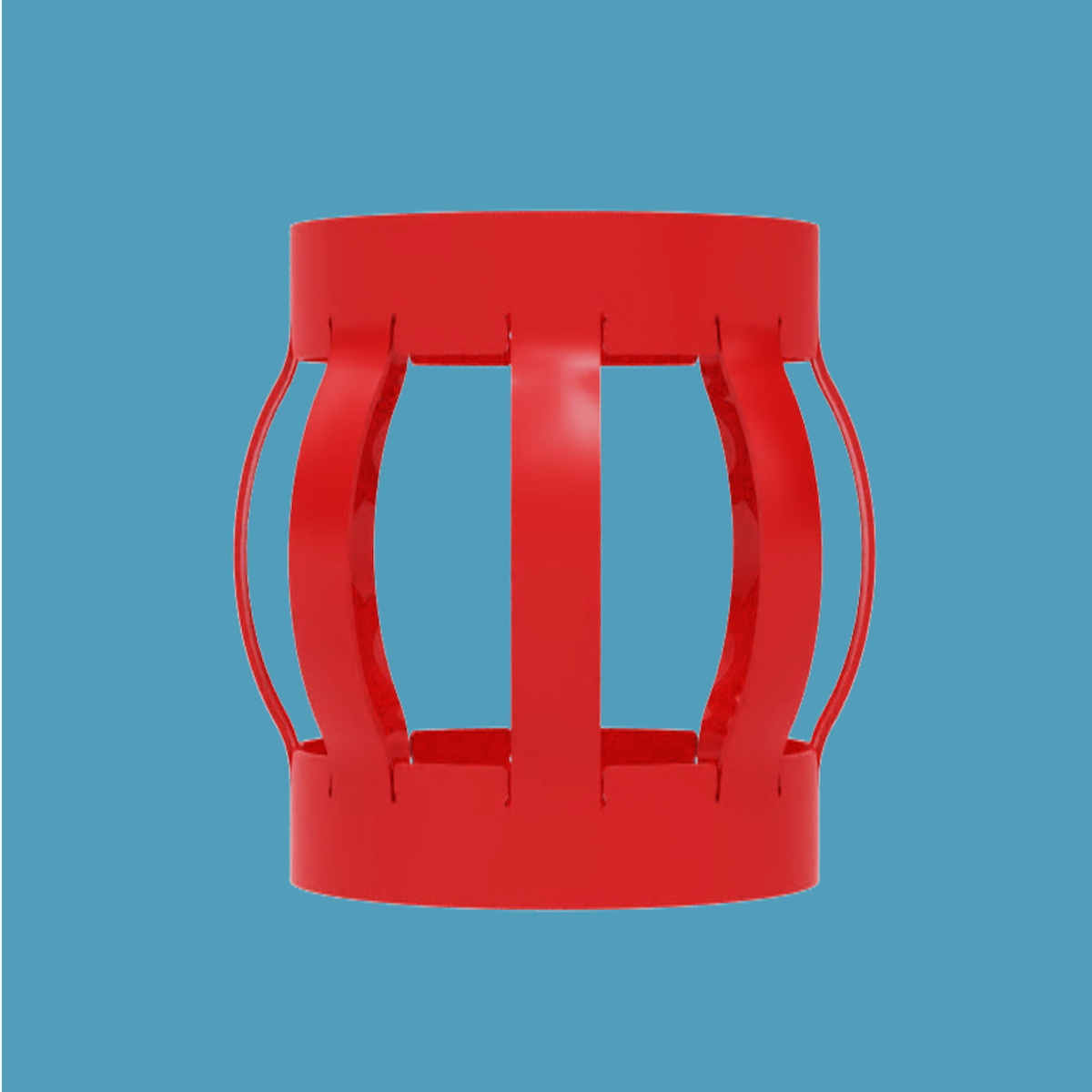

Centek conducted a simulation using the latest well trajectory and profile data. The revised modelling revealed that the original design provided insufficient standoff and required a full redesign. The number of centralizers was nearly doubled—ensuring above-API standoff across the entire cement column up to the previous casing shoe. Centek ES centralizers (0700-0812ES) and stop collars (0700-0SO) were selected as the optimal solution for the 7” casing job. The updated simulation and product selection were presented during a wellsite visit, where a comprehensive technical session was held with the Centek representative and the operator and global distributor.The session covered:

- The performance and benefits of Centek’s ES and S2 centralizers

- Proper stop collar installation methods

- Optimized spacing and installation best practices

THE RESULT

CUSTOMER TESTIMONIAL

"The installation was smooth, the cement job was excellent, and the final bond log confirmed we made the right choice."