NEWS The Unsung Hero of Centralization: Why Stop Collars Matter More Than You Might Think

In the complex world of well construction, centralizers often take center stage. But one small, often overlooked component plays a crucial role in ensuring their effectiveness: the stop collar.

Stop collars are essential to centralization performance. Their job is simple yet critical: hold the centralizer in its designed position on the casing to provide optimal standoff throughout the run-in-hole and the cementing process. When stop collars are incorrectly specified, installed poorly, or fail under load, the effectiveness of centralization—and the success of the well—can be compromised.

What Stop Collars Do—and Why Fit Matters

Stop collars are mechanical restraints designed to prevent axial movement of centralizers. They keep centralizers fixed at engineered intervals where optimal standoff is required to promote the most efficient run-in hole, effective mud removal and reliable cement placement.

If a stop collar doesn’t fit securely, or is installed incorrectly it can lead to:

- Poor centralizer spacing

- Reduced standoff / less than optimal centralization

- Inadequate cement coverage and channeling

- Increased risk of differential sticking

- Higher likelihood of remedial operations and NPT

Axial movement of stop collars can have a major impact. Under the API 10D-2 test procedure, stop collars are tested recording the force it takes to initiate axial movement and the force required to move the collar 4 inches on the casing. Operators should understand the implications of this tolerance and look beyond compliance to actual performance under downhole conditions.

Installation Matters: Set Screws, Torque, and Real-World Failures

Incorrect installation is one of the most common causes of stop collar failure. Many stop collars rely on set screws to grip the casing to maintain their position. While quick and convenient to install, these collars depend heavily on correct torque during installation.

If set screws are under-torqued, the collar may slip under the forces of casing movement. If over-torqued, the screws can strip or damage the collar body or casing surface. Competitor testing has shown that some suppliers either don’t provide torque specifications—or their products fail to hold even when installed to their own published instructions.

These inconsistencies pose a real risk to operations, particularly in challenging well environments. In contrast, Centek provides full torque guidance with every product and validates our performance under extreme conditions to deliver proven holding force.

Stop Collar Types: More Than Just Fitment

There are several types of stop collars available to suit different operational needs:

- Set screw collars: Common and easy to install, but torque must be applied precisely to ensure holding strength.

- Quick-latch or draw bolt style collars: Fast to fit on site but may lack the holding force required in demanding wells.

- Hinged collars with set screws: Useful where hinged collars are preferred

- Close tolerance stop collars: designed for close tolerance and under reamed applications. These often are costly and can require specialized installation.

At Centek, every stop collar is engineered for specific operational demands, tested to exceed holding force expectations, supported by installation instructions and torque guidelines to eliminate ambiguity on the rig floor. Our Centralizers and stop collars are specifically engineered to work together as a system. Used together and installed correctly they protect each other in the wellbore.

When a Small Component Makes a Big Impact

Stop collar failure is not a minor issue—it’s a major operational risk. A centralizer that moves from its intended location can undermine the performance of the entire string, resulting in poor zonal isolation, reduced cement bond, and increased risk of failure in production or abandonment phases.

That’s why Centek designs stop collars to work as an integral part of a complete centralization system. From engineering through manufacturing and testing, we ensure every collar delivers the strength and reliability needed in the world’s toughest wells.

In Summary

Stop collar performance is essential. API standards define performance and choosing the right product and installing it correctly is vital.

At Centek, we deliver stop collars that meet and exceed expectations—ensuring centralizers maintain intended spacing.

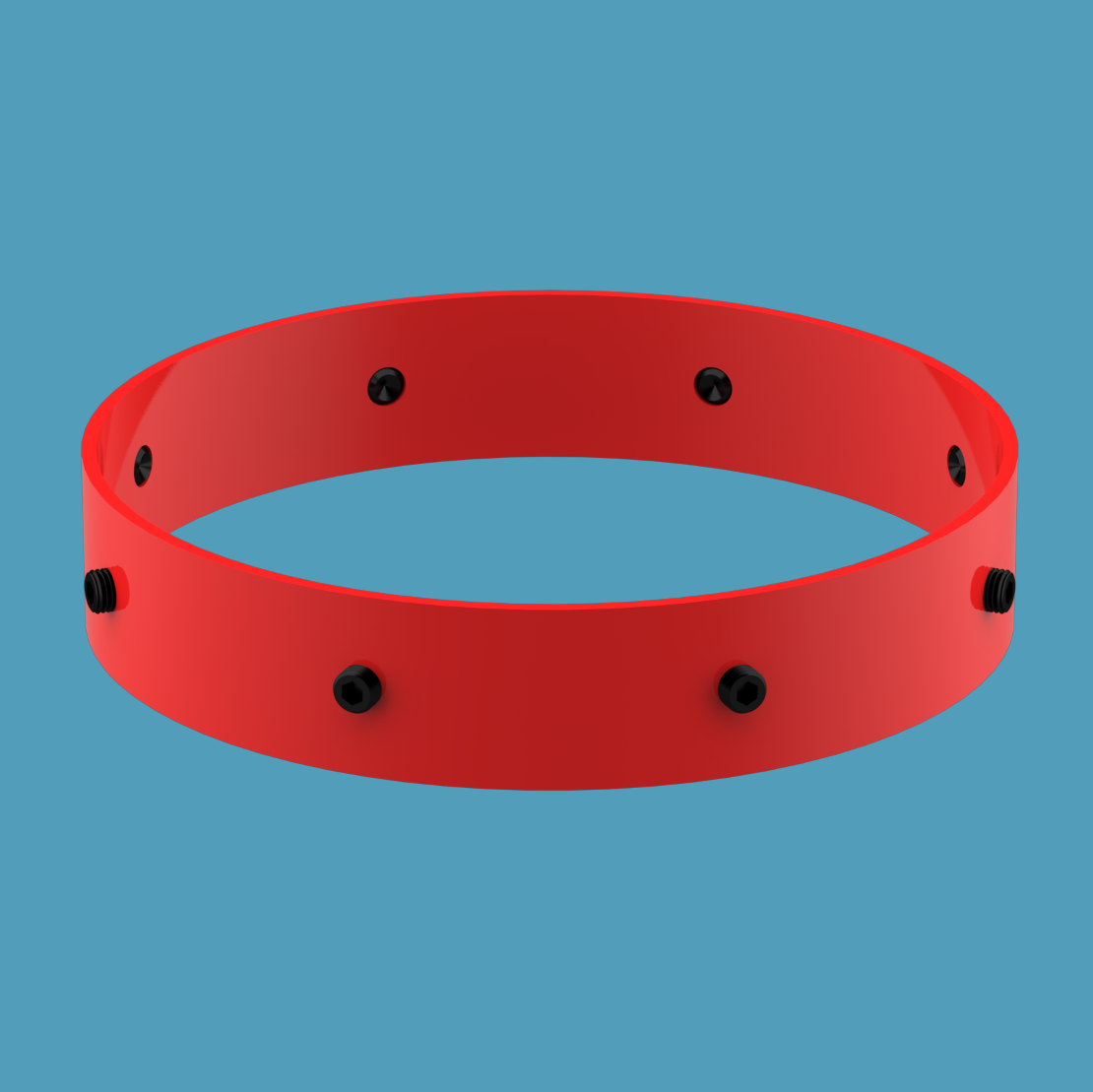

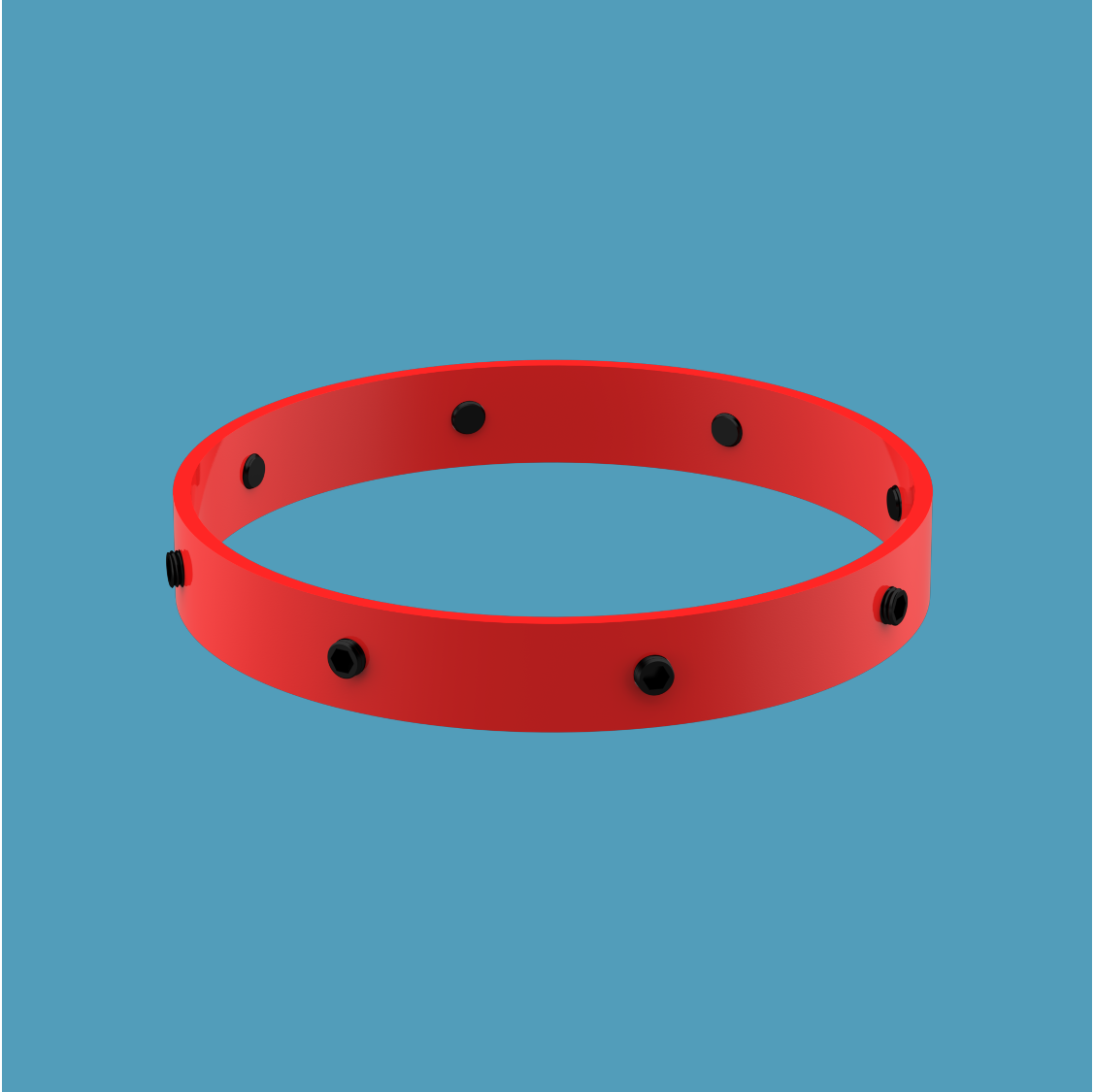

PRODUCTS USED00SO Slip on Stop Collar

High strength 00SO slip on stop collars are developed for use in challenging wells.

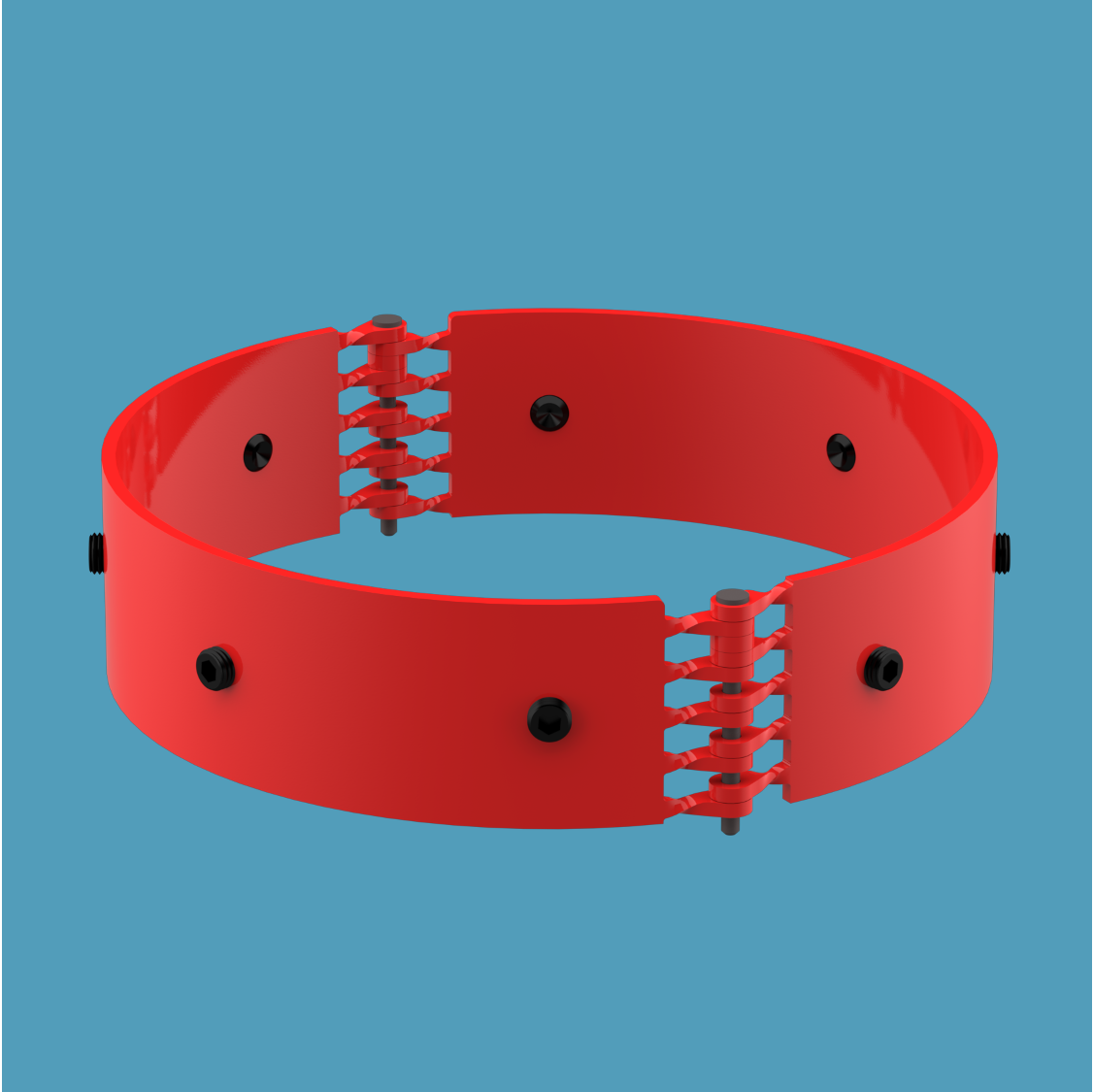

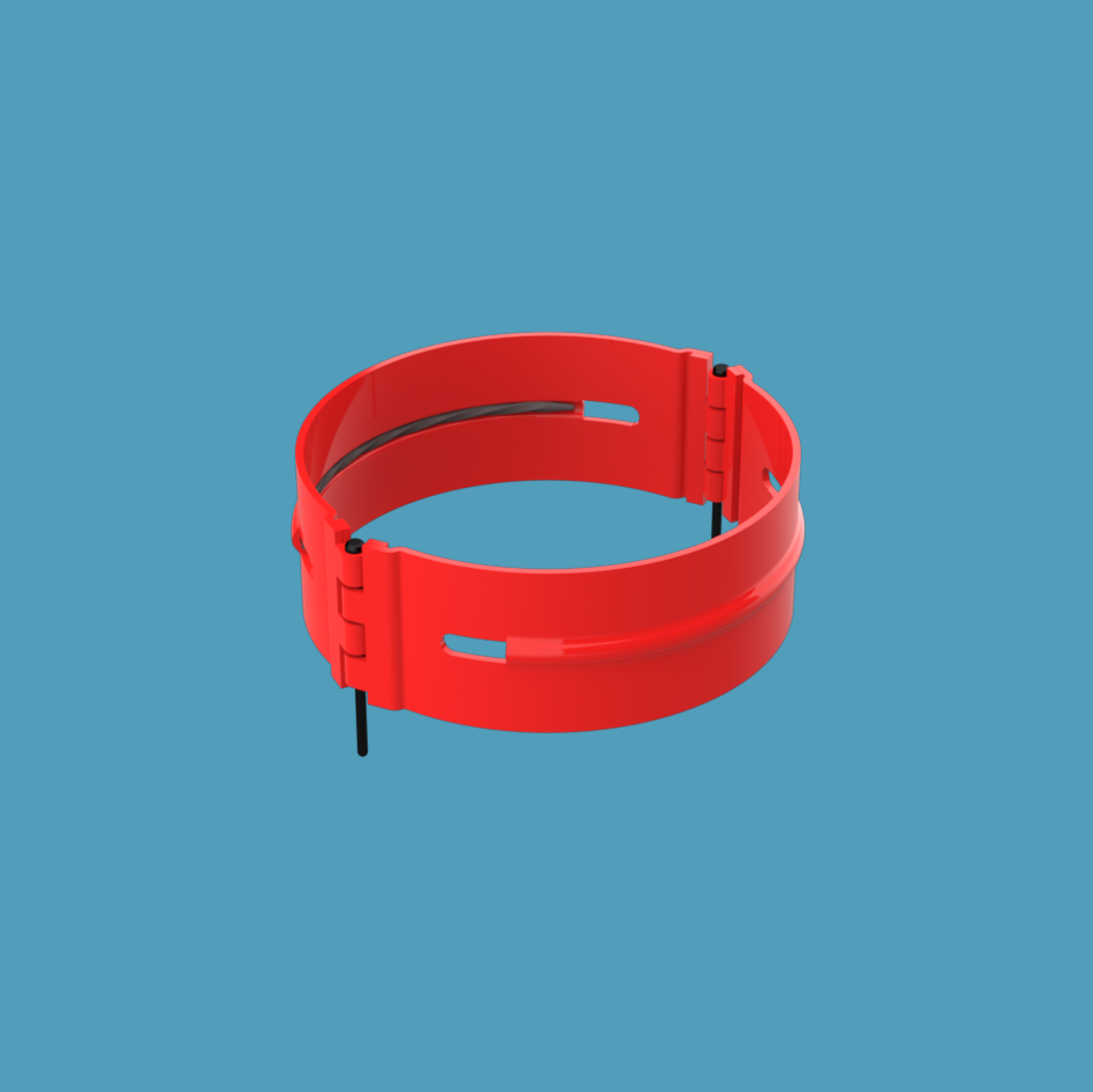

PRODUCTS USED00SH Hinged Stop Collar

The 00SH is a high strength stop collar developed for use in challenging wells with the same integrated hinge technology as the S2-H Hinged bow spring centralizer.

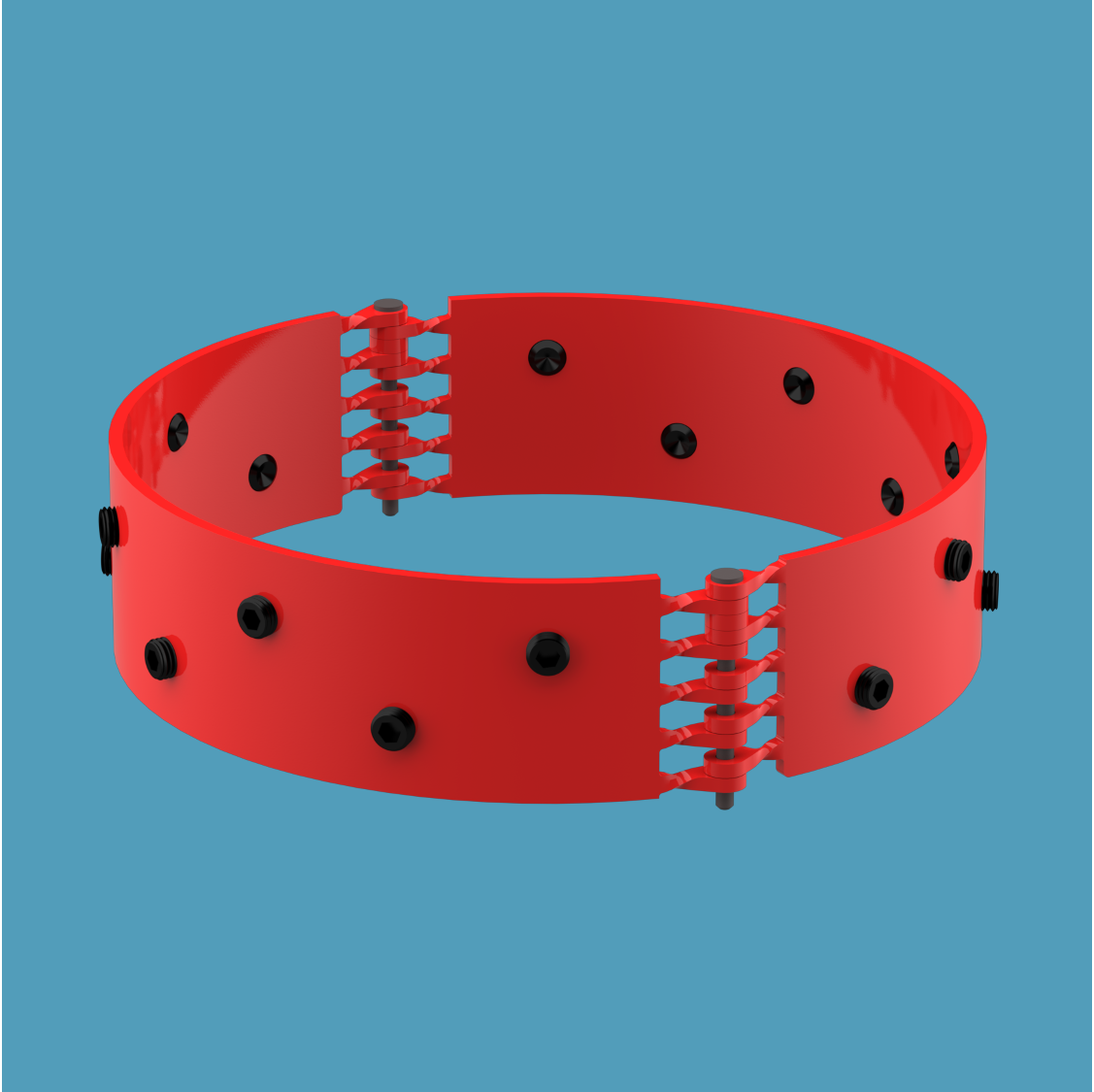

PRODUCTS USEDHDSO Heavy Duty, Slip on Stop Collar

The HDSO is a slip on, heavy duty stop collar developed for use in challenging wells where strength is a priority.

PRODUCTS USEDHDSH Heavy Duty, Hinged Stop Collar

Heavy duty hinged stop collar designed for use in challenging wells, where strength is a priority

PRODUCTS USED0SO Slip on Stop Collar

0SO slip on stop collars are developed for use in less challenging wells to complement our OBS-2 and OBW centralizers

PRODUCTS USEDHSN Hinged Stop Collar with Spiral Nail

The HSN is a stop collar with spiral nail installation for quick fitment in onshore wells and complements our range of hinged centralizers for vertical and horizontal wellbore sections.