CASE STUDY Centek S2s are rotated at TD in deep lateral in the Niobrara formation

THE CHALLENGE

Customers in the Rockies are utilizing different production liner and production casing well design techniques to complete their wells. They are looking for ways to have more productive wells that last longer without remedial intervention and repair.

In this region we see a major difference in choice of cementing versus non-cemented drilling and completion applications. For operators who have chosen the cemented completion design, we have demonstrated the field proven added value of using Centek centralizers.

In this example the operator in the needed a centralizer for 6” casing in their first horizontal well in the Piceance Basin (Grand Junction area). It was a deep lateral to about 12,000ft MD in the Niobrara formation.

They were concerned with achieving 3 goals during the primary cementing process;

1. getting the casing to bottom

2. the ability to rotate the casing

3. a satisfactory bond log result

THE SOLUTION

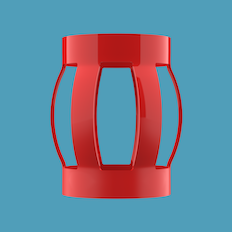

Centek S2 centralizers were chosen to meet these goals. The selection was made based on the unique Centek high performance slip-on non welded design. This centralizer could offer the best benefits for the customer’s well bore conditions. Halliburton iCEM and Centek Latload computer modeling programs were utilized to determine the best cement placement design possible and provide an optimal centralizer spacing program.

THE RESULT

All goals were achieved.

CUSTOMER TESTIMONIAL

"While on bottom in a 12,000ft well we were able to rotate at 60rpm and the bond log results were excellent"

Drilling Engineer