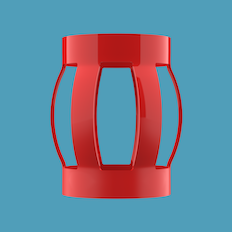

CASE STUDY Centek S2 reduces torque and drag and gets string to TD in spite of high build rates

THE CHALLENGE

Operator BBC encountered sticking and had difficulty landing extended reach open hole completions due to hole conditions and high build rates of more than 12-15 degrees in the D J Basin, Colorado

THE SOLUTION

Operator ran 234 each (1 per joint) of 4 1/2” x 6 1/8” Centek S2 centralizers, floated between casing collars and ahead of swellable packers from top of liner hanger at 5,420ft MD to TD at 15,749ft. 9.5# mud wt. / 12.5# cement wt.

THE RESULT

The S2 reduced the torque and drag BBC had been realizing on previous completions. Completion string landed at TD in spite of a build rate that climbed above 15 degrees from approximately 5,700ft - 5,800ft MD.

CUSTOMER TESTIMONIAL

"I was very sceptical about running this quantity of centralizers in the hole. The company man said he would bet money we’d have problems. The Centek centralizer got us to bottom under very difficult conditions."

Completions engineer, BBC