CASE STUDY Customer makes move to Centek Centralizers over solids

THE CHALLENGE

Operators today face tough decisions in choices of what products to use to help solve drilling and cementing challenges. It’s an easy decision to keep using the same products over and over where success has been achieved. When new products come along it can be tough to make a change without knowing if the new product will be better.

A UK customer operating offshore in the Southern North Sea, York Field, made that decision to change. The customer had been using positive stand-off centralizers on highly deviated wells.

These types of centralizers are typically under gauge and can only provide a certain amount of stand-off. The customer had a challenging well to complete where getting competent top of cement to a certain height in the annulus would be crucial to the life of the well.

The production liner was to be long and horizontal with a small annular clearance. The top of cement was needed up to the vertical curve of the heel of the well. This meant that good centralization would play a key role in achieving the desired TOC with rotation also being requested.

About the well:

This was a 7” near horizontal liner job with a TMD at 19,514ft and a TVD of 997ft . The well bore path would involve salt formations.

THE SOLUTION

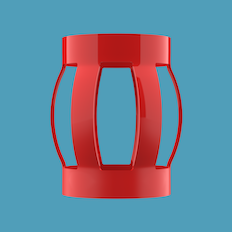

The Halliburton Cementing Engineer recommended using Centek S2 centralizers for this string to give the best possible stand-off. Simulations with competitors' solid type centralizers had shown insufficient stand-off.

After supplying simulations for various different well conditions and spacing layouts, as requested by the customer, it was demonstrated that running the liner and achieving rotation would not be a problem using the proposed Centek solution.

THE RESULT

The 7” liner was run to total depth without any problems and achieved rotation when on bottom. This allowed for good mud displacement and placement of cement around the liner. Slow pump rates had to be used due to low ECD constraints, but the Halliburton iCem 3D displacement software showed that with Centek centralization the job requirements could be achieved.

CUSTOMER TESTIMONIAL

The customer was very happy with the results and has now moved to using Centek centralizers on upcoming wells, stating:

"It was excellent news to read the details of last 7” liner cement job. Great bit of work to get the liner in the hole and rotating – well done and thanks for all the engineering effort that went into that job!"