Product Summary

Radical innovation at Centek in 2001 led to the development of a range of centralizers with superior downhole performance which have dramatically reduced failures and have proved for over 20 years to save operators time and cost getting to TD.

Bringing the best to the business was hard, staying there is tough but being an industry leader is far more rewarding than replicating others. As sector forerunners we’ve changed perceptions, standards and quality; set benchmarks and created a new category of centralizers, constantly enhancing our reputation as global market leaders.

All Centek centralizers deliver performance in 6 key areas, optimizing:

- Strength

- Flexibility

- Runability

- Flow by Area

- Pipe Rotation

- Stand-off

A full string offer

We now offer a full range of bow spring and solid body centralizers and slip on and latch on stop collars. We will work with you to find the best fit product for the job, balancing performance with economic factors.

Our in-depth understanding of your needs and the centralizer and stop collar market has enabled us to tailor our product offering to the requirements and preferences of each region - fulfilling the specific demands of each region. Our new range of welded and solid products provide Centek quality at a lower price point. These are developed for less challenging wells.

All of our products are built to perform as specified on their datasheets and our bow spring products are tested beyond the API standard.

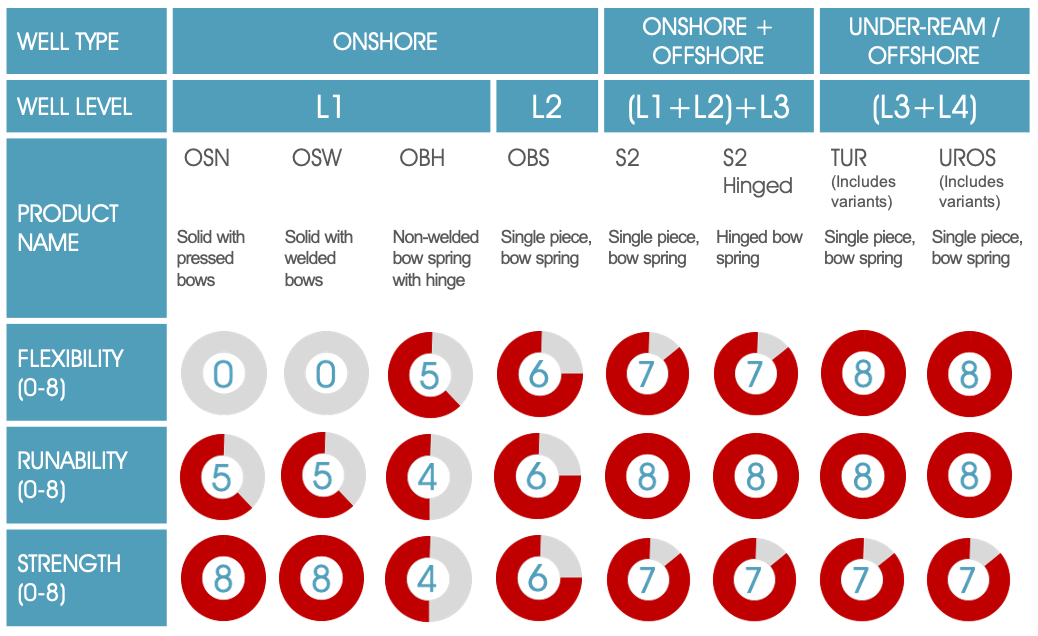

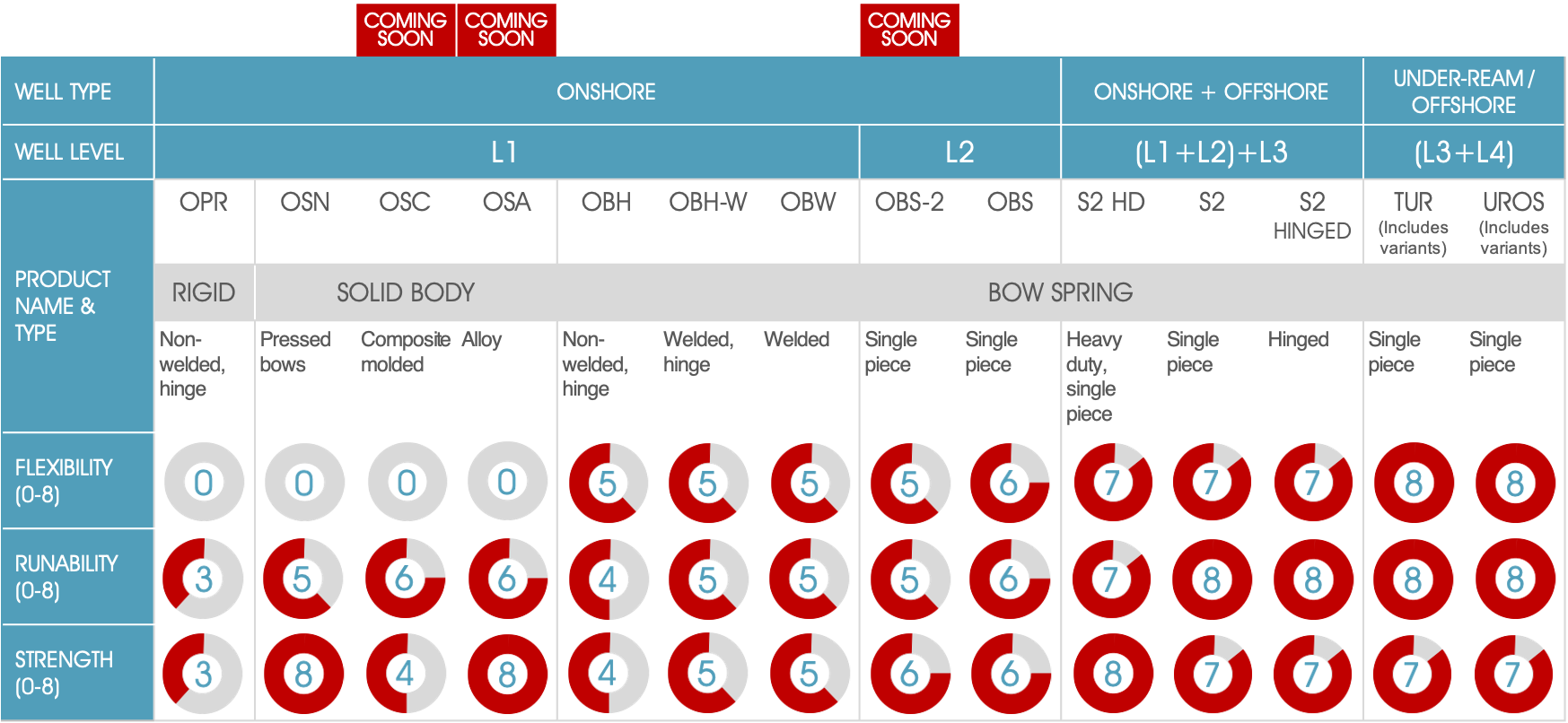

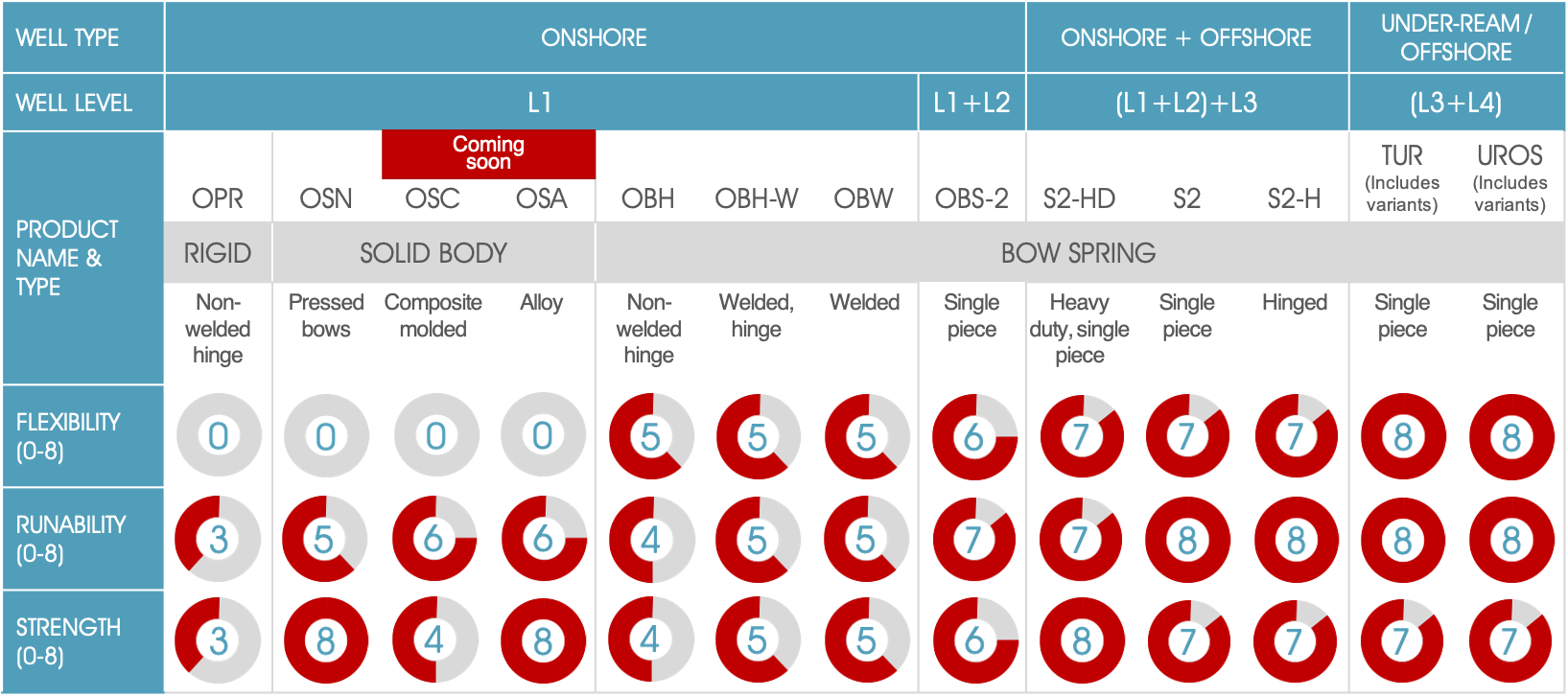

Ratings

Centralization and the ease of running casing is often a balance between strength and flexibility which combine to support, what we call, 'runability'. To help with product selection we've added a rating to all our products for flexibility, runability and inherent strength.

These ratings reflect the ease in which the centralizer can run in hole and mean that, when choosing the right product for the job, you can now consider these factors against the cost of the product and the challenges of the particular section of the well.

Centek Single Piece Centralizers

Revolutionary design and innovation

Centek one-piece centralizers are robust and ultra-high-strength with no weak points but with the flexibility and restoring force to absorb both axial and radial loads. They are manufactured to gauge and provide maximum stand-off, eliminating cement channeling. The patented bow spring design allows for flexibility when encountering tight spots with no compromise on performance integrity. These elements represent the most significant change in the centralizer industry in over 40 years.

Flexibility through under gauge conditions

Lack of integral centralizer strength or an intolerance to flexibility are some of the main causes of centralizer damage or stuck pipe in under-gauge well conditions. Pulling back or getting stuck in hole costs money and, with today’s rig rates, that can mean a lot of money. Worse, the well could be lost.

The Centek single piece unit dramatically enhances RIH of casing or liner strings due to its construction method and flexibility. Each centralizer is designed to compress to a near flat condition. During compression, through under-gauge conditions, the Centek bow spring centralizer is able to withstand the increased loads that will be encountered without damage or permanent deformation. Once a restriction has been negotiated it will expand to the open or cased hole ID.

Benefits of downhole flexibility:

1. Enhanced RIH in localized restrictions

2. No additional bit run

3. Centralizer integrity maintained

Flow by Area

Flow by area displacement relates directly to fluid regimes, such as volumes, velocity, density and pressure, which have a significant impact on primary cementing operations. Field results repeatedly show our bow spring centralizers significantly improve annular flow by area.

Pipe rotation

Pipe rotation is of critical importance when carrying out primary cement jobs. The aim is to agitate the pipe to enhance the cement displacement efficiency, improving mud removal and therefore providing a good cement bond and long term zonal isolation. Centek bow spring centralizers have been designed to greatly aid pipe rotation. The design of the centralizer allows a well centralized pipe to rotate inside the centralizer due to its extremely low coefficient of friction, while the centralizer is held in position against the borehole wall.

Using Centek centralizers can provide:

- Enhanced rotation due to optimized centralization

- Improved well clean out

- Superior cement job and good zonal isolation

- Minimum rotational torque loses

- Minimize stall out effect

Stand-off

API defines stand-off as ‘the smallest distance between the OD of the casing and the wellbore’. Stand-off ratio is the ratio of stand-off to the annular clearance for perfectly centered casing, expressed as a percentage. Stand-off is a measure of pipe eccentricity. In a static condition, when casing is perfectly centered, stand-off will be 100%. The degree of stand-off achieved by the centralizer is a critical factor while running casing and tubing when the objective is a good cement job. Pipe centralization (stand-off) has a major impact in many areas, but in cementing operations it will directly affect displacement efficiency.

Optimum displacement is an industry wide challenge for primary cementing. Factors that influence displacement efficiency of fluids are typically:

- Well geometry

- Pipe centralization

- Pipe movement

- Fluid velocity

- Fluid properties

- Fluid regimes

- Fluid volumes

- ECD constraints vs loss of circulation

All Centek single piece centralizers offer optimum stand-off capability in most well conditions due to their robust yet flexible performance providing enhanced results against all these factors. Improved stand-off quickly translates into improved:

- RIH

- Cementation operations

- Pipe centralization

- ECDs which may allow increased pump rates

- Well clean-out

Optimum stand-off also has the result of reducing cement channeling and remedial works in addition to minimizing low points of pipe in the well.

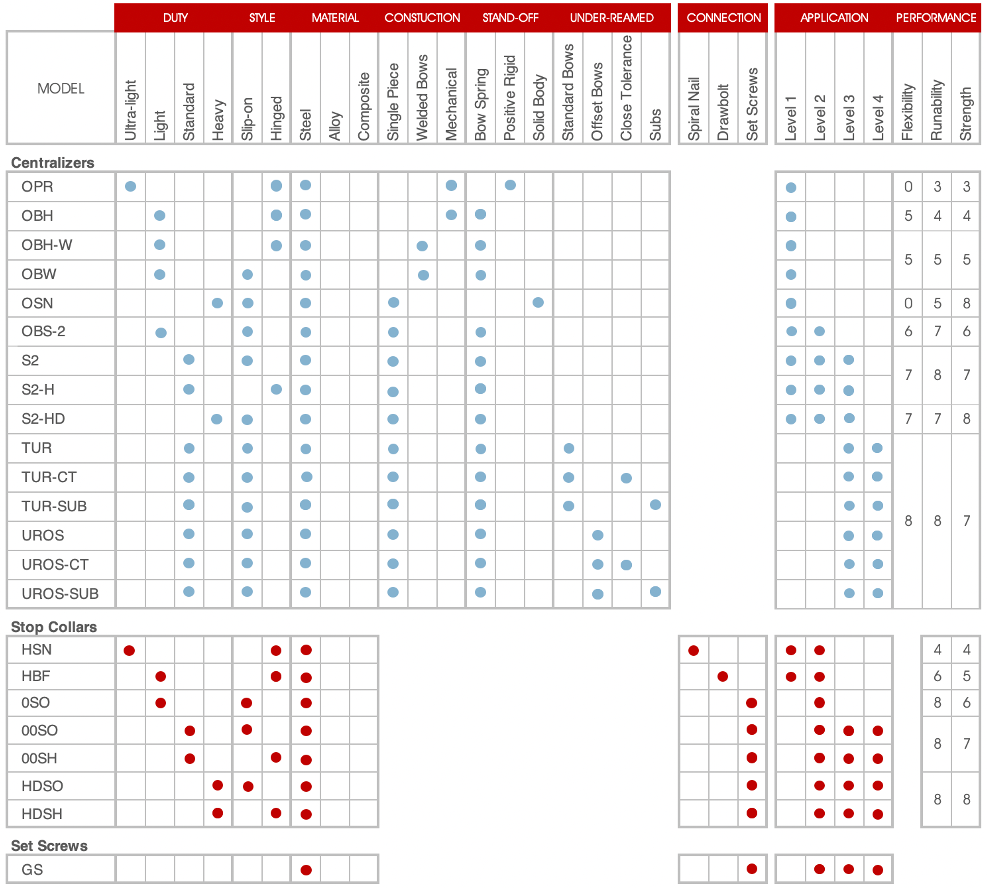

Product range by style, application and performance

For more information on our products talk to our Product Service Experts today or use our Product Selector Tool to find the right product for your application.