CASE STUDY Using Centek S2 achieved an average reduction in liner running time of 23%*

Vertechs Oil & Gas Technology is a major oil and gas field services supplier with headquarters in Chengdu, China. The company has been involved in drilling activities in the South Sichuan basin, where the wells have long horizontal sections and the well bore quality is often poor. These are onshore wells with a TVD (true vertical depth) of 900 meters and horizontal sections of typically 1,000 meters in length. There is a dog leg with a severity of around 12deg/30m.

THE CHALLENGE

Vertech’s initial use of locally manufactured centralizers, both rigid and conventional bow-spring types, led to significant running time delays.

The rigid centralizers were metal alloy and failed to get to total depth (TD). When the drill team pulled the casing out of the hole they found the rigid centralizers had broken and left fragments downhole.

The rigid alloy centralizers were not strong enough to bear the side forces in horizontal wells. The welded bow spring centralizers also proved susceptible to damage and were unsatisfactory because they could not maintain restoring force in the open hole resulting in poor casing centralization and bad cementation.

THE SOLUTION

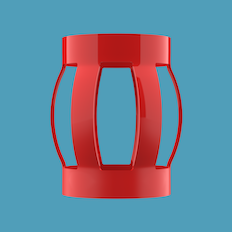

The use of Centek 5.5” x 8.5” S2 centralizers realized a reduction in torque and also drag. The surface area contact was reduced, coupled with improved stand-off ratios, allowed the pipe to remain more central to the bore hole creating the best optimum RIH conditions.

THE RESULT

The Centek S2 achieved an average reduction in liner running time of 23% or 11 hours per well*, compared to using the previous rigid centralizers in similar horizontal wells. The average liner running time in this project was around two days.

CUSTOMER TESTIMONIAL

"The main benefit of the Centek S2s has been their performance downhole, helping casing to run to TD compared to wells with other centralizers where the casing got stuck or ran 100 – 200 meters short of TD, resulting in yields being substantially reduced compared to plan."

Gary Zhang, General Manager Vertechs Oil & Gas Technology Co., Ltd.

*compared to using the previous rigid centralizers in similar horizontal wells.